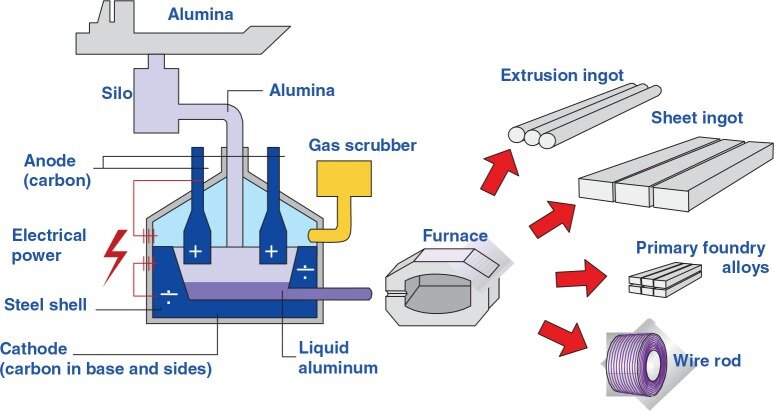

Aluminum Supply Chain

General Explanation: The Aluminum Group offers raw materials, intermediates, and finished products for aluminum production, catering to lightweight, corrosion-resistant applications.

Applications: Supports aluminum smelting and alloy production for aerospace, automotive, construction, and electronics.

Range of Specifications: Meets ISO 9001 and ASTM standards, with alumina purity > 98%, ingot purity of 99.7-99.9%, refractories rated up to 1800°C.

Bauxite (Aluminum Hydroxide)

General Explanation: Primary ore for aluminum production, rich in aluminum hydroxide.

Applications: Used in alumina refineries to produce aluminum oxide.

Range of Specifications: Al₂O₃ content 40-60%, lump sizes 0-100 mm, silica < 7%.

Alumina

General Explanation: Refined aluminum oxide used as the primary material in aluminum smelting.

Applications: Essential for aluminum production, also used in ceramics and refractories.

Range of Specifications: Purity > 98.5%, particle size 50-150 µm, sodium < 0.4%.

AlF3 (Aluminum Fluoride)

General Explanation: A critical additive in aluminum smelting, reducing alumina’s melting point and improving electrolysis efficiency.

Applications: Enhances energy efficiency in aluminum smelting plants.

Range of Specifications: Purity > 98%, particle size 20-100 µm, low impurities (Fe₂O₃ < 0.05%).

Cryolite

General Explanation: A flux in aluminum smelting, reducing energy requirements and improving efficiency.

Applications: Enhances conductivity in aluminum smelting.

Range of Specifications: Purity > 98%, Na₃AlF₆ content > 95%, particle size 0-10 mm.

Anode Carbon Block

General Explanation: Carbon or metal-based components collecting molten aluminum in smelting.

Applications: Used in aluminum smelting cells.

Range of Specifications: Carbon-based (resistivity < 30 µΩm) or metal-based with high corrosion resistance.

Cathode Carbon Blocks

General Explanation: Carbon or metal-based components collecting molten aluminum in smelting.

Applications: Used in aluminum smelting cells.

Range of Specifications: Carbon-based (resistivity < 30 µΩm) or metal-based with high corrosion resistance.

Silicon Metal

General Explanation: High-purity silicon used to produce aluminum alloys with enhanced mechanical properties.

Applications: Incorporated into alloys for automotive, aerospace, and construction.

Range of Specifications: Silicon content 98.5-99.5%, lump sizes 10-100 mm, low iron (< 0.5%).

Coal Tar Pitch (CTP)

General Explanation: A binder material for aluminum anode production, ensuring durability and conductivity.

Applications: Used in anode manufacturing and carbon products.

Range of Specifications: Softening point 100-120°C, carbon > 80%, ash < 0.5%.

Calcined Petroleum Coke (CPC)

General Explanation: High-purity carbon used in aluminum anode production and steelmaking.

Applications: Used in anode manufacturing and as a recarburizer.

Range of Specifications: Carbon > 98%, sulfur < 1%, particle size 0-50 mm.

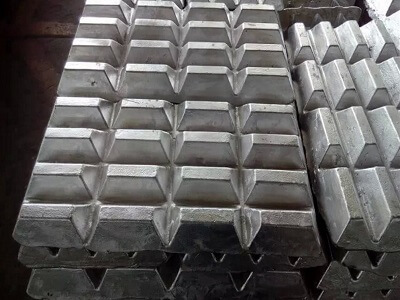

Pure Aluminum

General Explanation: High-purity aluminum used as a base material for manufacturing.

Applications: Used in casting, extrusion, and rolling for automotive, aerospace, and packaging.

Range of Specifications: Purity 99.7-99.9%, ingot weight 20-25 kg, low impurities (Fe < 0.2%, Si < 0.1%).

Aluminum Rod

General Explanation: Lightweight, corrosion-resistant aluminum rods for industrial applications.

Applications: Used in electrical conductors, construction, and automotive components.

Range of Specifications: Diameters 9-20 mm, purity > 99.7%, tensile strength 150-300 MPa.

Aluminum Hardeners

General Explanation: Alloying agents enhancing aluminum alloys’ mechanical properties.

Applications: Used in aerospace, automotive, and structural alloy production.

Range of Specifications: Contains Ti, Cr, or Mn (5-10%), tablet or ingot form.