Colored Metals and Additives

General Explanation: Specialized alloys and additives enhancing steel and metal properties for advanced metallurgical processes.

Applications: Used in steelmaking, foundries, and alloy production for automotive, aerospace, and energy industries.

Range of Specifications: Ferroalloys meet ASTM/ISO standards, alloy content 10-80%, carbon varying by type, tailored particle sizes.

Ferro Manganese - High Carbon

General Explanation: Ferroalloy with high carbon, adding manganese for steel strength.

Applications: Used in carbon steel for construction.

Range of Specifications: Mn 70-80%, C 6-8%, lump size 10-100 mm.

Ferro Manganese - Low Carbon

General Explanation: Low-carbon ferroalloy for high-quality steel with minimal carbon.

Applications: Used in precision and stainless steel.

Range of Specifications: Mn 80-85%, C < 0.5%, lump size 10-50 mm.

Ferro Silico Manganese

General Explanation: Combines silicon and manganese, used as a deoxidizer and alloying agent.

Applications: Used in construction and structural steels.

Range of Specifications: Mn 60-70%, Si 15-20%, C < 2%, lump size 10-100 mm.

Ferro Chrome - High Carbon

General Explanation: High-carbon ferroalloy adding chromium for corrosion resistance.

Applications: Used in stainless steel for appliances and equipment.

Range of Specifications: Cr 60-70%, C 6-8%, lump size 10-100 mm.

Ferro Chrome - Middle Carbon

General Explanation: Moderate carbon ferroalloy for balanced stainless steel.

Applications: Used in automotive and construction stainless steel.

Range of Specifications: Cr 65-70%, C 1-2%, lump size 10-80 mm.

Ferro Chrome - Low Carbon

General Explanation: Low-carbon ferroalloy for high-grade stainless steel.

Applications: Used in medical and aerospace stainless steel.

Range of Specifications: Cr 65-70%, C < 0.1%, lump size 10-50 mm.

Ferro Vanadium

General Explanation: Adds vanadium to steel, enhancing strength and toughness.

Applications: Used in HSLA steels for pipelines and automotive.

Range of Specifications: V 50-80%, lump size 10-50 mm, C < 0.2%.

Ferro Niobium

General Explanation: Adds niobium to steel, improving strength and weldability.

Applications: Used in HSLA steels for bridges and automotive.

Range of Specifications: Nb 60-70%, lump size 10-50 mm, C < 0.2%.

Ferro Titanium

General Explanation: Adds titanium to steel, acting as a deoxidizer and grain refiner.

Applications: Used in stainless and specialty steels for aerospace.

Range of Specifications: Ti 30-40%, lump size 10-50 mm, C < 0.1%.

Ferro Phosphorus

General Explanation: Adds phosphorus to steel, enhancing strength and corrosion resistance.

Applications: Used in specialty steels.

Range of Specifications: P 20-25%, lump size 10-50 mm, C < 1%.

Ferro Silicon Zirconium

General Explanation: Adds silicon and zirconium to steel, improving deoxidation and corrosion resistance.

Applications: Used in high-strength automotive and structural steels.

Range of Specifications: Si 40-50%, Zr 30-40%, lump size 10-50 mm.

Raw Petroleum Coke (RPC)

General Explanation: Solid carbonaceous material from crude oil refining, serving as a feedstock for calcination or as fuel.

Applications: Aluminum anode production, graphite electrode manufacturing, fuel in industrial kilns.

Range of Specifications: Fixed carbon 80–90%, sulfur 1–6%, volatile matter 8–15%.

Coking Coal (Metallurgical Coke)

General Explanation: Carbon-rich material derived from coking coal, providing heat and carbon source for metallurgical processes.

Applications: Iron and steelmaking blast furnaces, foundries, and non-ferrous metal smelting.

Range of Specifications: Fixed carbon ≥ 85%, ash ≤ 12%, volatile matter ≤ 1.5%, sulfur ≤ 0.7%.

Calcined Petroleum Coke (CPC)

General Explanation: High-purity carbon material obtained by heating RPC to remove volatile matter.

Applications: Aluminum smelting anodes, graphite electrodes, carbon additives in steelmaking.

Range of Specifications: Fixed carbon ≥ 98.5%, sulfur ≤ 0.7%, real density ≥ 2.05 g/cm³.

Graphite Petroleum Coke (GPC)

General Explanation: High-carbon recarburizer produced by graphitizing petroleum coke at high temperatures.

Applications: Carbon additive in steel and foundry industries, improving carbon content and purity.

Range of Specifications: Fixed carbon ≥ 98.5%, sulfur ≤ 0.05%, ash ≤ 0.5%.

Needle Coke

General Explanation: Premium-grade petroleum coke with a needle-like crystalline structure, enabling high conductivity.

Applications: Ultra-high power graphite electrodes, lithium-ion battery anodes.

Range of Specifications: Fixed carbon ≥ 99%, sulfur ≤ 0.5%, coefficient of thermal expansion ≤ 1.0 × 10⁻⁶/°C.

Calcined Anthracite

General Explanation: Anthracite coal heat-treated to improve carbon content and reduce volatile matter.

Applications: Carbon additive in steelmaking, cathode material in aluminum smelting.

Range of Specifications: Fixed carbon ≥ 95%, sulfur ≤ 0.5%, volatile matter ≤ 1.5%.

Carbon Black

General Explanation: Fine carbon powder produced from incomplete combustion of hydrocarbons, with high surface area.

Applications: Reinforcing filler in rubber, pigment in plastics, inks, and coatings.

Range of Specifications: Particle size 10–500 nm, iodine adsorption 30–150 mg/g, tint strength ≥ 100%.

Ramming Paste

General Explanation: Carbonaceous paste used for the lining of blast furnaces and other high-temperature vessels.

Applications: Furnace hearth lining, hot and cold ramming in metallurgical installations.

Range of Specifications: Softening point 70–120°C, volatile matter ≤ 8%, fixed carbon ≥ 85%.

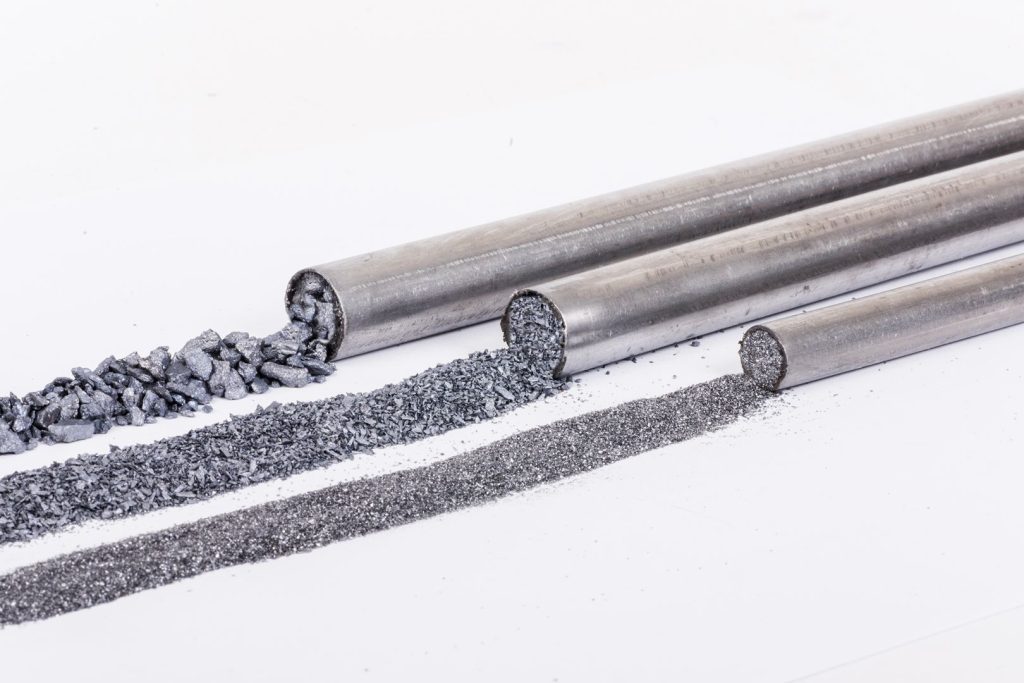

Cored Wire

General Explanation: Steel wire encapsulating powdered additives for precise alloying in molten metal treatment.

Applications: Desulfurization, deoxidation, and microalloying in steel production.

Range of Specifications: Diameter 9–16 mm, wire weight 250–500 kg/coil, core fill ratio 15–35%.

Carbon Additive

General Explanation: High-carbon material used to increase carbon content in molten metal.

Applications: Foundry and steelmaking processes to achieve desired carbon specifications.

Range of Specifications: Fixed carbon 90–99%, sulfur ≤ 0.5%, ash ≤ 5%.