Steel Supply Chain

General Explanation: The Steel Group provides essential raw materials and semi-finished products for steel production, meeting the rigorous demands of industries like construction, automotive, and infrastructure.

Applications: Used in blast furnaces, electric arc furnaces, and rolling mills for producing steel products such as rebar, slabs, and billets for construction and industrial manufacturing.

Range of Specifications: Products meet ASTM, ISO, and DIN standards, with iron content of 60-70% for ores, pellet sizes of 9-16 mm, and DRI/HBI metallization rates of 90-94%.

Hematite Iron Ore

General Explanation: A primary raw material for steelmaking, known for its high iron content and availability.

Applications: Utilized in blast furnaces and sintering plants for construction and industrial steel.

Range of Specifications: Iron content of 62-70%, low phosphorus (< 0.08%), sulfur (< 0.05%), lump or fine forms (0-10 mm).

Magnetite Iron Ore

General Explanation: A high-grade iron ore with magnetic properties, valued for its high iron content and ease of processing.

Applications: Used in blast furnaces and direct reduction plants for efficient steel production.

Range of Specifications: Iron content of 60-68%, low impurities (SiO₂ < 5%, Al₂O₃ < 2%), particle sizes 0-10 mm (concentrates) to 10-40 mm (lumps).

Iron Ore Concentrate

General Explanation: A finely processed product with high iron purity, enhancing steel production efficiency.

Applications: Used in pelletizing and sintering for steel manufacturing.

Range of Specifications: Iron content of 66-70%, particle size < 0.1 mm, low impurities (SiO₂ < 4%, P < 0.05%).

Iron Ore Pellets

General Explanation: Small, spherical balls of iron ore optimized for steelmaking furnaces due to uniform size and high iron content.

Applications: Employed in blast furnaces and direct reduction plants for automotive and construction steel.

Range of Specifications: Iron content of 65-68%, pellet diameter 9-16 mm, compressive strength > 2500 N/pellet, silica < 5%.

DRI (Direct Reduced Iron)

General Explanation: Sponge iron produced by reducing iron ore, offering high-purity feedstock for steelmaking.

Applications: Used in electric arc furnaces for construction, automotive, and machinery steel.

Range of Specifications: Metallization rate of 90-94%, iron content of 88-92%, carbon 1-2.5%, lump or pellet form.

HBI (Hot Briquetted Iron)

General Explanation: Compacted DRI designed for safe handling and transport, with high iron content.

Applications: Utilized in electric arc and basic oxygen furnaces for infrastructure steel.

Range of Specifications: Metallization rate of 92-95%, iron content of 90-93%, density > 5 g/cm³, briquette size 90-110 mm.

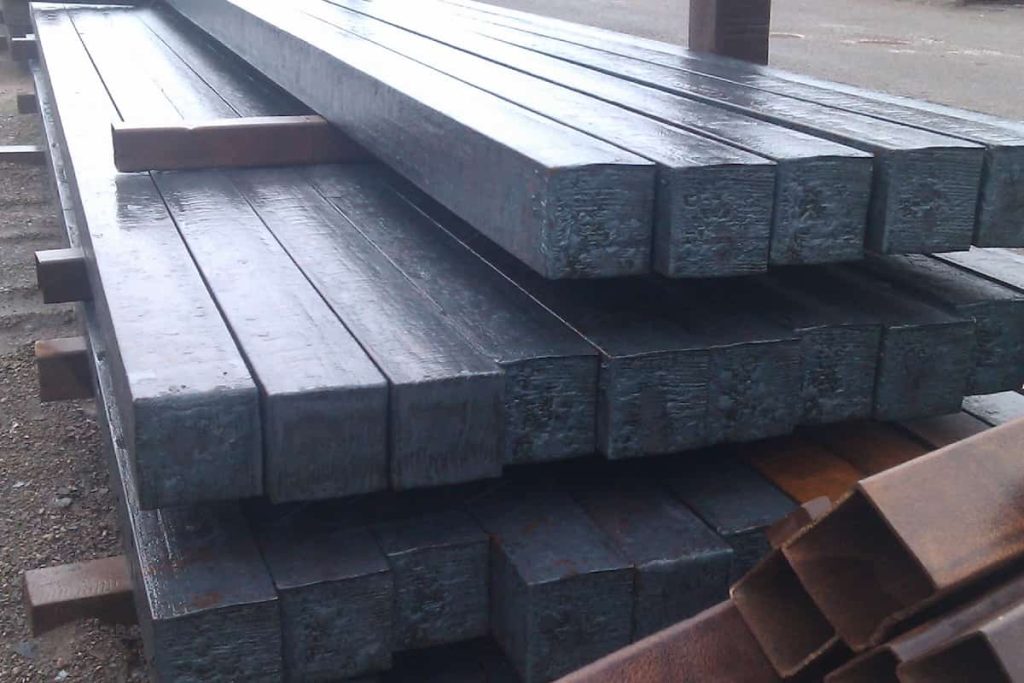

Slab & Billet

General Explanation: Semi-finished steel products for rolling mills to produce flat or long steel products.

Applications: Slabs for plates/sheets (automotive, shipbuilding), billets for bars/rods (construction).

Range of Specifications: Slabs (width 800-2000 mm, thickness 150-300 mm), billets (100×100 mm to 200×200 mm), ASTM/EN standards.

Rebar

General Explanation: Reinforcing bars providing tensile strength to concrete in construction.

Applications: Used in buildings, bridges, and infrastructure projects.

Range of Specifications: Diameters 8-40 mm, ASTM A615 (Gr. 40, 60, 75), tensile strength 400-600 MPa.